Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Harnessing the skies has long been humanity’s grandest dream, but today it is becoming a tangible reality—thanks to electric vertical take‑off and landing aircraft, or eVTOLs. In the last six months, the world has watched as companies from Boeing to startup Seven Aviation unveil prototypes that promise a future where city‑to‑city travel is faster, cleaner, and far less noisy than the familiar jetliners of the past. The United Nations Climate Summit on sustainability goals has electrified this ambition even further: governments are pledging to cut carbon emissions by 50% by 2030, and a growing part of that strategy hinges on the advent of low‑emission electric flight.

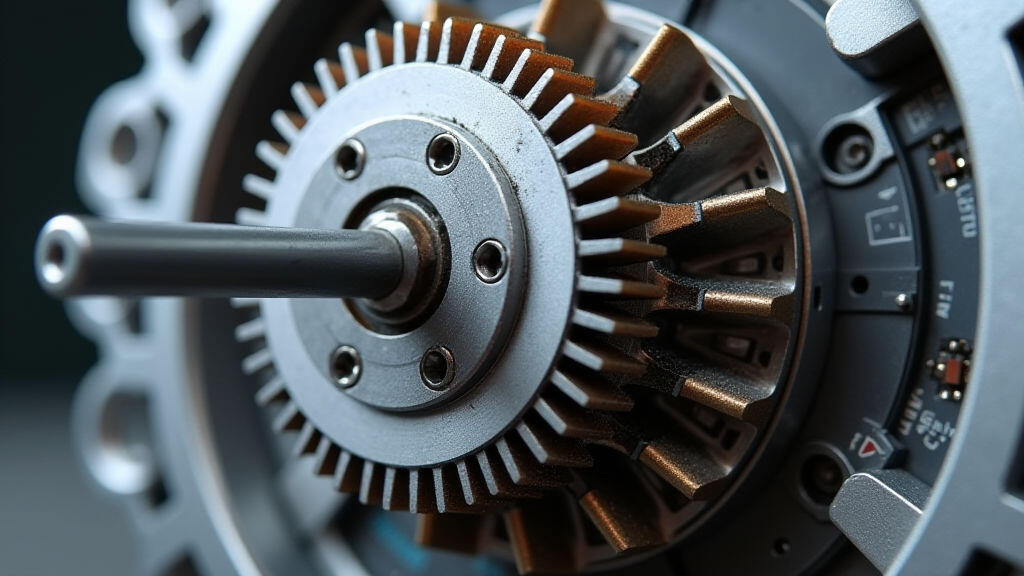

Yet behind these headlines of soaring prototypes and bold announcements lies a technical engine room that often goes unseen: the gear motor, also known as a reducer motor. This humble yet vital component sits at the heart of every electric propulsion system, translating high‑speed, low‑torque electric motor output into controllable thrust and steering forces required for flight. In this article we’ll explore why gear motors are not just a buzzword but a linchpin of the eVTOL revolution, what current market trends reveal about their growing importance, and how they are shaping the future of green aviation.

According to a recent report in Aviation Week & Space Technology, the eVTOL market is set to exceed $30 billion by 2035, driven by rising demand for urban air mobility (UAM) and declining battery costs. This surge is reflected not only in the commercial sector but also in public policy: the U.S. Federal Aviation Administration (FAA) has released a flexible certification pathway for eVTOLs, and European regulators are aligning similarly. Headlines across Bloomberg, Reuters, and our social‑media feeds report success stories—Boeing’s new electric cargo prototype hovered above downtown Philadelphia in late July, while PAL Aviation’s V4 carried its first passenger in Singapore this fall.

These milestones cover the critical triad of electric flight: 1) Performance—i.e., the ability to hover and maneuver, 2) Efficiency—fuel‑savings and lower emissions, and 3) Scalability—the ability to manufacture and maintain the aircraft at scale. The gear motor sits at the intersection of these goals.

An eVTOL’s battery pack is heavy, and any additional weight dramatically reduces flight time. Gear motors excel by converting a high‑speed, lightweight electric motor into a powerful low‑speed output. This reduction means engineers can use smaller motors for the same torque, cutting weight without sacrificing performance. A typical gear motor can provide over 90 % transmission efficiency, translating into more useful flight time on a single charge—an essential advantage for urban operators who need to stay profitable.

Flight control demands a high level of precision; small adjustments at the motor level allow aircraft to twist, tilt, and maintain stability. Gear motors incorporate integrated electronic speed controllers (ESCs) that facilitate fine adjustment of torque and speed. This fine‑tuned control reduces vibration and wear, extending component life and reducing maintenance costs—an irresistible proposition for operators with tight budgets.

Most eVTOLs use coaxially mounted rotors or distributed thrust. Space is at a premium, but gear motors are designed to be thin and stackable, easily fitting inside the aircraft’s frame without requiring bulky shafting or bulky brackets. Their compactness is vital for integrating into planned urban air vehicle layouts and for keeping the center of gravity near the ideal point.

Recent market analyses indicate that gear motor manufacturers are pivoting to meet new demands. The "energy‑to‑flight" segment is forcing firms to innovate in materials—such as lightweight alloys and carbon‑fiber housings—and in precision manufacturing techniques like 3‑D printed gear teeth. Statista projects that revenue from industrial gear motors will rise 12 % CAGR from 2024 to 2029, largely driven by the aerospace and electric vehicle sectors.

One notable product trend is the adoption of hexagonal gear geometry instead of traditional spur gears. Hexagonal forms can handle higher torque loads while decreasing bearing stress, a feature that directly benefits eVTOL systems that must endure frequent acceleration and deceleration cycles.

Consider the example of Seven Aviation’s Thunder, a 5‑passenger eVTOL that completed a 15‑minute flight over Manhattan in mid‑August. Engineers highlighted that its air‑to‐fuel conversion efficiency—thanks to a state‑of‑the‑art gear motor—hit an NREL‑ranking 48 kWh per flight hour, far ahead of the industry average.

Similarly, PAL Aviation’s V4 featured 16 gear motors, each rated at 250 Nm of torque. By employing a dual‑motor gearbox, the V4 could reduce its overall mass by 18 % compared to earlier models, directly translating into higher payload capacity.

In each of these examples, gear motors were not just an accessory but a strategic design choice that amplified the vehicle’s performance reach.

Looking ahead, the convergence of artificial intelligence and robotics is set to enhance gear motor capabilities. Predictive diagnostics powered by onboard sensors can anticipate wear before failure, ensuring real‑time maintenance scheduling. Digital twins—virtual replicas of physical gear motors—track usage patterns and optimize design for next‑generation eVTOLs.

Furthermore, integration of foldable gear motor housings promises to support modular eVTOL platforms, where manufacturers swap gear modules to tailor aircraft for specific roles—cargo, passenger, or emergency response.

The eVTOL wave sweeping across cities worldwide is fuelled by more than just electric motors. It’s the gear motor—small, efficient, and profoundly versatile—underpinning the transformation of urban air mobility. As battery chemistries improve, regulatory frameworks mature, and market demands intensify, the role of gear motors will only grow. They will keep aircraft lighter, more reliable, and easier to maintain, thereby increasing adoption rates and accelerating the shift towards a cleaner, faster, and more connected world.

To stay ahead, manufacturers and operators alike must recognize gear motors not as background components but as essential drivers of innovation. Their capacity to deliver precise torque, efficient power conversion, and compact design makes them indispensable to the future of electric flight—a future where airports may be replaced by sky‑ports and every commute could be an airborne journey.

Leave A Reply

Your email address will not be published. Required fiels are marked